ECCOSORB® Official Distributor and Stockist

ABOUT TECHNI3

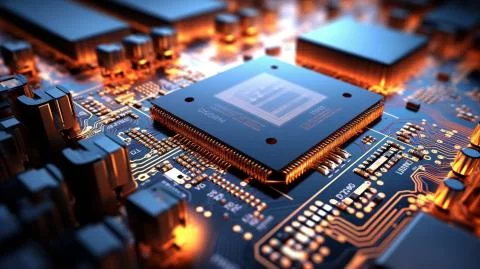

Providing cutting-edge innovation that enhances the protection of premium electronics.

Established in 2008 in South Wales, UK, Techni3 Ltd are the official distributor for LAIRD PERFORMANCE MATERIALS, (a Dupont business), in the UK and Ireland. With over three decades of experience, Techni3’s skilled engineers specialize in EMI shielding, Microwave absorption, and thermal dissipation.

Laird, a Global leader and manufacturer of performance materials, partnered with Techni3 as their official channel partner, stockist, and converter in the UK and Ireland. This collaboration enables Techni3 to provide cutting-edge innovations, enhancing the protection of premium electronics in the UK and Europe.

Read More

At Techni3, we offer a comprehensive and competitive engineering service marked by responsiveness and reliability. Our sales team and engineers engage with client engineers on-site, offering guidance and design solutions to various industries including Military, Military Aerospace, Automotive, Commercial Aerospace, Electronics, Space Science, EV Battery, and Pharmaceuticals.

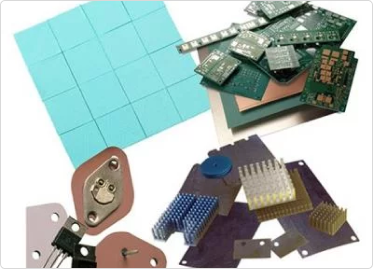

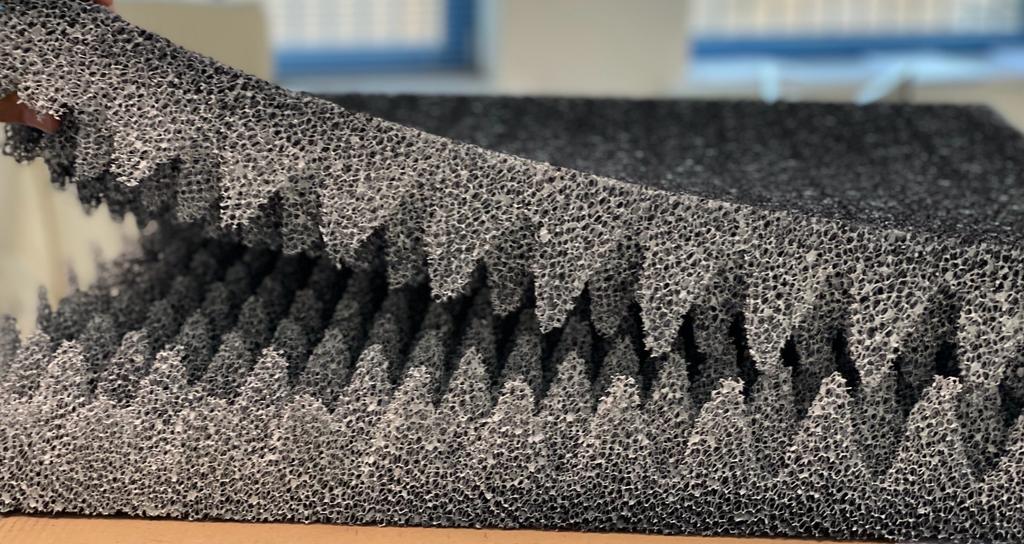

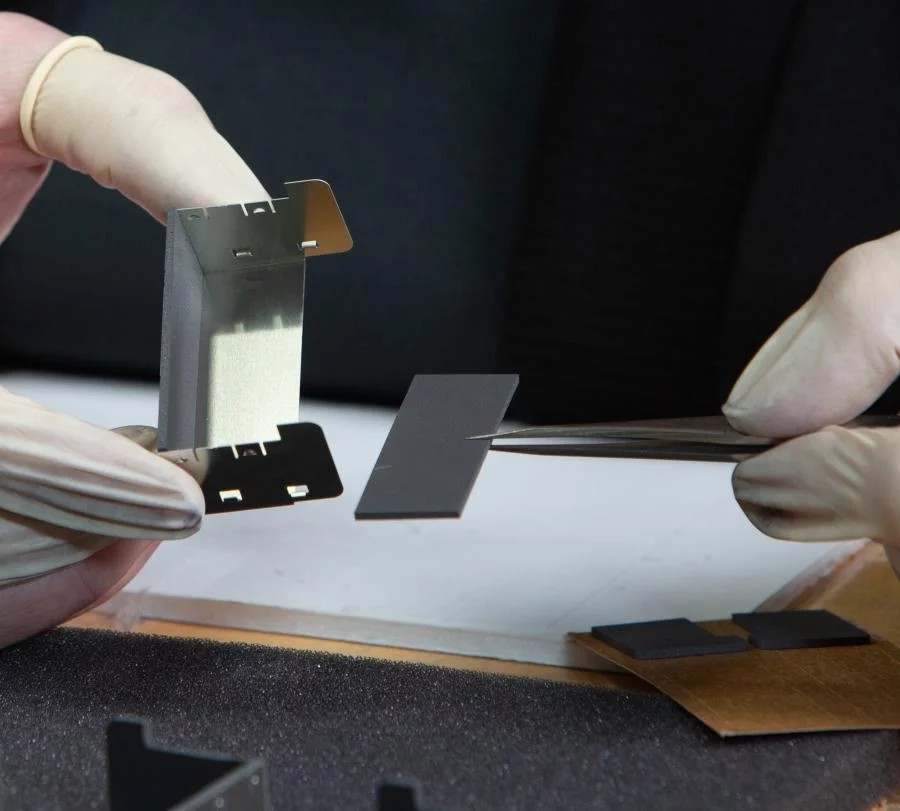

Our strength lies in turnkey solutions, including design specifications, prototype development, verification testing, and application expertise. This proficiency addresses challenges related to RF and thermal issues, establishing Techni3 as the definitive partner for intricate engineering problems.

For your design, manufacturing, and engineering needs, Techni3 stands as your solution provider, backed by global leader LAIRD. Our expertise lies in the supply and transformation of LAIRD raw sheet materials into meticulously crafted components, catering to the needs of elite electronic corporations throughout the UK, Ireland, and Europe. This operation is conducted with utmost efficiency, leveraging a comprehensive stock of Laird raw materials at our central facility located in South Wales, UK

At Techni3, we offer a comprehensive and competitive engineering service marked by responsiveness and reliability. Our sales team and engineers engage with client engineers on-site, offering guidance and design solutions to various industries including Military, Military Aerospace, Automotive, Commercial Aerospace, Electronics, Space Science, EV Battery, and Pharmaceuticals.

Our strength lies in turnkey solutions, including design specifications, prototype development, verification testing, and application expertise. This proficiency addresses challenges related to RF and thermal issues, establishing Techni3 as the definitive partner for intricate engineering problems.

For your design, manufacturing, and engineering needs, Techni3 stands as your solution provider, backed by global leader LAIRD. Our expertise lies in the supply and transformation of LAIRD raw sheet materials into meticulously crafted components, catering to the needs of elite electronic corporations throughout the UK, Ireland, and Europe. This operation is conducted with utmost efficiency, leveraging a comprehensive stock of Laird raw materials at our central facility located in South Wales, UK

Explore Markets

We are a trusted partner to the world’s leading technology brands

Our Experience

Providing a professional and personal approach to your design engineering requirements

We design, develop and deliver industry leading solutions that protect electronics. Enhancing performance and reliability for our customers.

Our world-class materials science and engineering expertise provides the depth and breadth to solve the most complex problems.

Committed to designing innovative, custom solutions that address current challenges while proactively anticipating those of the future.

Global Distribution. ECIA-Approved.

Laird is a member of the Electronic Components Industry Association (ECIA). As a key components industry supplier, we provide solutions to distributors serving electronics manufacturing.

New Product Release

Laird Latest